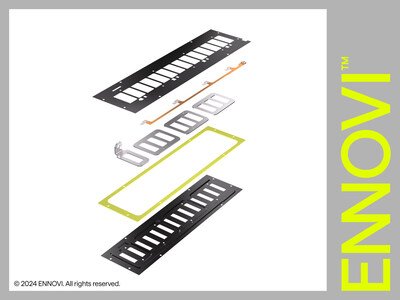

E-mobility specialist ENNOVI has launched the ENNOVI-CellConnect-Pouch – a new cell contacting system designed for the battery manufacturers favoring the pouch cell form factor. The new cell contacting system prioritizes cost-effectiveness, faster manufacturing cycle time, and protection against thermal runaway with advanced lamination and FDC technologies.

ENNOVI’s advanced lamination technology ensures the structural integrity and durability of the battery pack. Utilizing flexible die-cut circuit (FDC) technology for the low voltage signal traces, instead of a conventional flexible printed circuit (FPC), reduces production time and costs while minimizing environmental impact.

The upper dielectric layer incorporates the FDC copper traces, while the lower layer is pre-cut to the shape of the current collectors. Both layers are made of automotive-grade PI or PET material with good electrical insulation and temperature stability properties. The two layers are laminated together with all built-in fuse traces or surface mount fuses and NTC temperature sensors layered in between, streamlining material usage and creating a thin design. The overall design also helps mitigate battery thermal runaway by achieving a fast exhaust release time.

“With the ENNOVI-CellConnect-Pouch cell contacting system we offer battery manufacturers a total vertically integrated production solution enabling us to produce a part at a lower cycle time using hot lamination. The system’s design removes the need for traditional plastic cell carriers, made out of glass-reinforced plastic, and eliminates the carrier storage and molding lines, and heat staking process.”

Gustavo Cibrian, Product Manager, ENNOVI