MAN Engines has developed a new MAN BatteryPack, aiming to simplify and improve electricity storage in the industrial sector. Based on the nickel-manganese-cobalt (NMC) technology, MAN’s new battery solution boasts a modular design and offers customers the flexibility to individually scale the capacity and performance of their energy storage systems for different energy requirements in order to optimally reflect their specific needs.

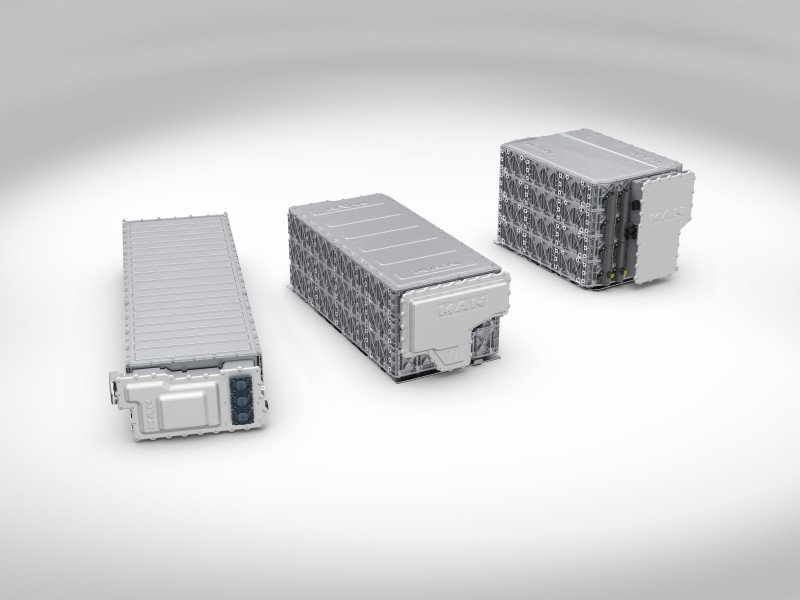

A MAN BatteryPack, also known as a battery system, generally consists of several battery modules arranged in two to four layers within the housing. Each of these modules contains many battery cells. Different modules can be arranged in different ways to produce different designs of MAN BatteryPacks. A MAN BatteryPack stores 89 kWh of energy, of which 80 kWh can be used. Due to the three varying shapes – from almost square to elongated – there are a wide range of integration options in different installation spaces. Currently, up to six MAN BatteryPacks can be combined to achieve a total system capacity of up to 534 kWh gross (480 kWh net). Expansion to other packs for higher capacities is being planned.

MAN Engines’ many years of experience in the customer-specific development of diesel and gas engines for various applications in agricultural and railway technology, shipping and power generation will now also be transferred to battery production. With their in-depth industry know-how, the engineers at MAN Engines optimize existing engines and assemblies to create leading drive solutions. This expertise makes it possible to offer industrial customers tailor-made battery solutions from the large-scale production of MAN vehicle technology. Thanks to large-scale production at the Nuremberg plant of MAN Truck & Bus and a global service network, customers benefit from established processes and advantages, such as meeting the requirements for the European Battery Regulation.

MAN Truck & Bus – and thus also MAN Engines – considers the entire life cycle of the battery to be a closed cycle up to recycling. The overarching goal in dealing with batteries is to close the material cycle in order to make a major contribution to more sustainable development. To this end, MAN will automatically assess the condition of batteries that can no longer be used for a specific application and then dismantle them. For further use, reuse in a new application is considered after appropriate reprocessing. After the aforementioned factory repair (2nd-use) of the batteries or in the event that batteries are no longer suitable for stationary buffer storage systems of solar, wind power or biogas plants after their first use or after an accident (2nd-life), recycling comes into play. MAN will implement a closed cycle for battery raw materials with the primary goal of continuously extending the use of batteries and thus resources. Only when this is no longer possible will the valuable, recovered raw materials such as nickel, manganese, cobalt or lithium flow into the production of new batteries. MAN is part of the Volkswagen Group recycling network with recycling partners throughout Europe.

“We see MAN BatteryPacks in mobile charging solutions that are exposed to high loads and at the same time have to meet a variety of different operating conditions. Compared to other cell chemistries, NMC cell chemistry offers a high energy density, which is very crucial for mobile applications.”

Reiner Roessner, Head of Sales MAN Engines